The most important features for a professional Studio Equipment Trolley Case in 2025 include superior protection, robust maneuverability, intelligent organization, durable construction, and future-proof adaptability. Equipment often suffers from impact, vibration, moisture, and dust during transit. A quality case safeguards investments, preventing these common issues. It also ensures effortless transport and efficient workflow.

Key Takeaways

- A good studio trolley case protects your gear. It stops damage from bumps, weather, and dust. This keeps your equipment safe.

- The best cases help you move gear easily. They have strong wheels and comfortable handles. This makes transport simple.

- Smart cases keep your tools organized. They have special spaces for all your items. This helps you work faster and better.

1. Superior Protection for Your Studio Equipment Trolley Case: Safeguarding Your Investment

Impact Resistance for Valuable Gear

Professional studio equipment faces constant movement and potential hazards. A high-quality Studio Equipment Trolley Case offers robust impact resistance, protecting valuable gear from accidental drops and bumps. Manufacturers construct these cases with advanced, rigid materials that absorb and disperse kinetic energy effectively. This design prevents damage to sensitive components, ensuring equipment remains operational and reliable.

Weatherproofing and Environmental Defense

Environmental factors pose significant threats to electronic equipment. A superior Studio Equipment Trolley Case features advanced weatherproofing, shielding contents from rain, dust, and humidity. Integrated seals and durable exterior shells create a protective barrier. This defense mechanism prevents moisture ingress and keeps fine particles out, maintaining optimal conditions for delicate electronics in any environment.

Internal Padding and Customization for a Snug Fit

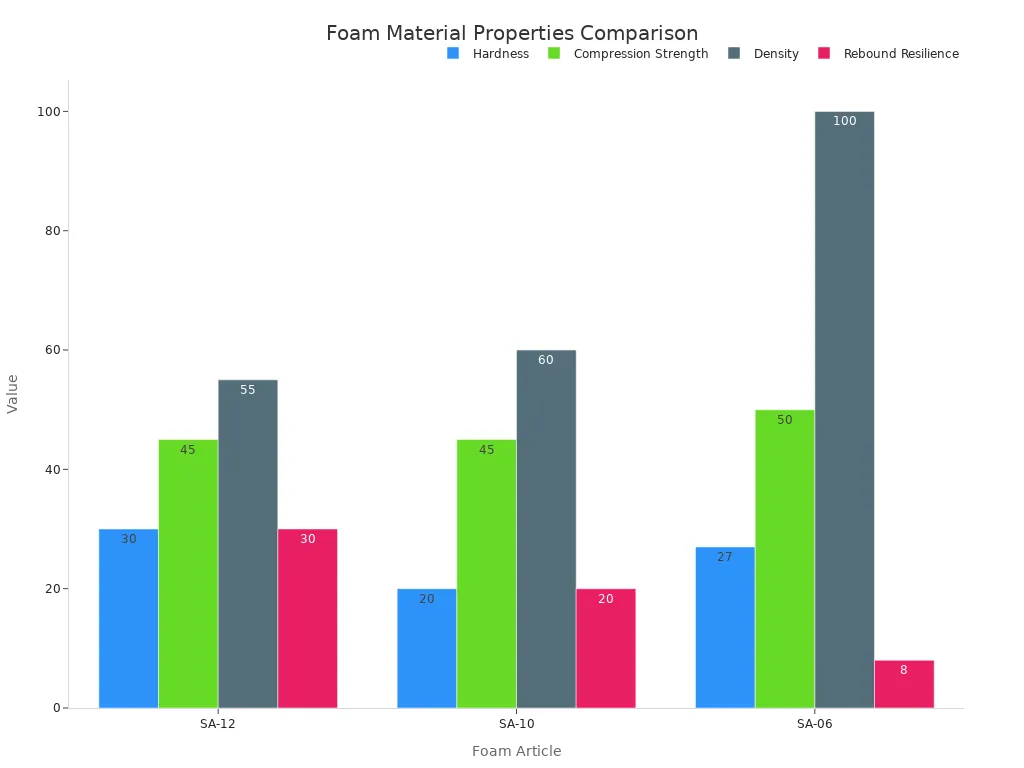

Internal padding provides a crucial layer of defense, securing equipment against internal movement and vibration. Manufacturers utilize specialized foam materials to cradle sensitive gear. For instance, Polyurethane (PU) foam offers excellent energy absorption and flexibility, while Expanded Polyethylene (EPE) foam provides a balance of impact resistance and structural rigidity. For superior durability and structural integrity, Cross-Linked Polyethylene (XLPE) foam resists deformation and retains its shape, ideal for high-value items. Polyolefin (closed-cell) foam excels in shock absorption and durability, resisting wear and tear. These specialized foams, like the SA Series, demonstrate exceptional shock absorption and vibration dampening, reducing injury risk and enhancing stability.

Customizable compartments and adjustable dividers allow professionals to create a snug fit for each piece of equipment. This tailored approach minimizes shifting during transport, further preventing potential damage.

2. Robust Maneuverability in a Studio Equipment Trolley Case: Effortless Transport

High-Quality Wheels for All Terrains

Effortless transport relies heavily on superior wheel design. A professional Studio Equipment Trolley Case features high-quality wheels that navigate diverse studio environments and outdoor locations. Manufacturers often select polyurethane wheels for their versatility in mixed settings, balancing durability with floor protection. For sound-sensitive studios, rubber wheels offer excellent shock absorption and quiet operation. Nylon or plastic wheels suit specialized needs requiring lightweight and chemical resistance. Wheel hardness also matters; a Shore D60 rating provides a good balance of durability, load capacity, and floor protection. Caster configurations enhance mobility. A setup with two fixed and two swivel wheels offers stability and maneuverability. Alternatively, four swivel wheels with two locking mechanisms provide maximum flexibility and secure positioning.

Ergonomic Telescoping Handle Design

An ergonomic telescoping handle significantly reduces strain during transport. Professionals often move heavy gear, so the handle must offer comfort and control. Padded handles are crucial; they minimize physical strain and fatigue during prolonged use. A well-designed handle extends smoothly to multiple heights, accommodating users of different statures. Its robust construction prevents wobbling, ensuring stable control over the loaded case. This design allows for easy navigation through crowded spaces or over uneven surfaces.

Versatile Additional Handles for Lifting

Beyond the main telescoping handle, versatile additional handles are essential for practical lifting. Side handles allow two people to carry heavier cases with ease. Top handles provide a quick grip for short distances or when lifting the case into a vehicle. These strategically placed handles distribute weight effectively, preventing awkward lifting postures. They enhance overall usability, making the Studio Equipment Trolley Case adaptable to various loading and unloading scenarios.

3. Intelligent Organization in Your Studio Equipment Trolley Case: Streamlined Workflow

Modular Interiors and Customizable Compartments

Modular interior systems are crucial for organizing diverse studio equipment. These systems efficiently utilize both horizontal and vertical space. They allow for stacking and reconfiguring units, adapting to changing needs. This scalability means storage can grow with the studio’s equipment inventory. Modular designs enable clear categorization of diverse gear through options like drawers, cabinets, and shelving. This reduces clutter and minimizes time spent searching for items. It improves workflow, leading to increased productivity and better inventory management. Robust materials like heavy-duty steel ensure durability, protecting valuable studio equipment from damage.

Dedicated Accessory Pockets for Essentials

Professionals often carry numerous small, critical accessories. Dedicated accessory pockets keep these essentials organized and readily available. These pockets prevent small items from getting lost among larger equipment. They ensure quick retrieval of cables, batteries, memory cards, and adapters. Well-designed pockets often feature transparent materials or labels for easy identification. This thoughtful organization saves valuable time during setup and breakdown.

Quick Access Design for Efficiency

An efficient Studio Equipment Trolley Case prioritizes quick access to all contents. Detachable inserts for specific items like laptops or cameras allow for tailored organization and rapid retrieval. Interchangeable packing cubes help organize smaller accessories, making them easy to identify and access. Smart packing strategies, such as grouping items by purpose, further enhance accessibility. This design philosophy ensures professionals can locate and deploy their gear swiftly, maintaining a smooth workflow on any shoot.

4. Durable Construction of a Professional Studio Equipment Trolley Case: Built to Last

Advanced Material Science for Longevity

A professional Studio Equipment Trolley Case demands materials that withstand rigorous use. Manufacturers increasingly turn to advanced material science for superior longevity. Hybrid materials, such as composites integrating FRP and steel, offer an excellent strength-to-weight ratio. This combination provides the lightweight and corrosion-resistant properties of FRP with the strength and rigidity of steel. Furthermore, carbon fiber epoxy composites deliver exceptional tensile strength. Kevlar (Aramid fiber) composites offer superior impact strength and overall mechanical properties, making them ideal for robust yet lightweight case construction. These materials ensure the case protects valuable gear for many years.

Heavy-Duty Hardware Quality

The reliability of a professional case also depends on its hardware. High-quality latches, hinges, and handles are crucial for security and functionality. Heavy-duty T-hinges, for example, support large panels and doors effectively. Manufacturers construct these hinges from high-grade steel for durability. Many T-hinges feature zinc-plating to guard against corrosion, maximizing their service life. Options with thermoplastic Delrin bushings enhance wear resistance, reduce friction, and prevent creaking. Stainless steel hardware offers even greater corrosion resistance for harsh environments. Rigorous durability testing and ISO certification ensure these components meet or exceed industry standards for performance.

Reinforcement at Stress Points

Even with advanced materials and hardware, specific areas of a case experience more stress. Manufacturers strategically reinforce these critical points to prevent premature wear and failure. Corners, edges, handle attachment points, and wheel mounts are common stress zones. Reinforcement often involves thicker material, integrated metal plates, or specialized fasteners. This targeted strengthening ensures the case maintains its structural integrity even under heavy loads and frequent handling. Such attention to detail guarantees the case remains reliable throughout its lifespan.

5. Future-Proof Adaptability for Your Studio Equipment Trolley Case: Evolving with Your Gear

Expandability Options for Growing Needs

Professional studios constantly acquire new equipment. A future-proof Studio Equipment Trolley Case offers robust expandability options. This design allows professionals to adjust the case’s capacity as their gear collection grows. Features like adjustable internal dividers, removable trays, or even stackable modules provide this flexibility. Users can reconfigure the interior to fit larger items or add more smaller accessories. This adaptability ensures the case remains a valuable asset for years, eliminating the need for frequent replacements.

Integrated Technology for Modern Demands

Modern studio workflows often rely on integrated technology. Advanced trolley cases now incorporate features that meet these demands. Examples include built-in USB charging ports for devices, internal LED lighting for visibility in low-light conditions, or even GPS trackers for security and asset management. Some cases offer integrated power distribution systems, simplifying setup on location. These technological enhancements streamline operations and add significant convenience for busy professionals.

Modular System Compatibility for Versatility

Modular systems offer immense versatility for audio professionals. A well-designed trolley case supports these systems, enhancing their portability and utility. Modular studio outboard systems, like the 500-series, benefit greatly from dedicated transport solutions. These systems allow users to reconfigure signal flow and drastically alter sounds with the same modules. Many professionals prefer the physical interaction of hardware modular systems over software emulations. Modular racks offer superior space efficiency; for instance, 11 1176-style compressors can fit into just 3U of rack space. This compact size allows more equipment to be accessible and easily transported. Modular systems also prove more economical than 19-inch rack gear, as module manufacturers save on power supply costs. This often makes 500-series versions considerably more affordable. Larger modular racks provide enhanced value and room for future expansion. Single-slot hosts can transform any 500-series module into a standalone product, further increasing flexibility.

6. Optimizing Mobility and Payload Capacity in a Studio Equipment Trolley Case

Optimizing mobility and payload capacity in a Studio Equipment Trolley Case involves thoughtful design choices. These choices ensure professionals can transport their gear efficiently and safely.

Balancing Lightweight Design with Robustness

Manufacturers achieve an optimal balance between lightweight construction and robust protection. They utilize technologically advanced materials. For softside luggage, stain-resistant, moisture-resistant polyester and ballistic nylon offer durability. Hardside suitcases often feature scratch-resistant polycarbonate that flexes upon impact. Component engineering also plays a vital role. Wheels, extension handles, and carry handles are designed to be lightweight yet ultra-sturdy. These components support significant weight without adding bulk. An integrated design philosophy prioritizes extreme durability and minimal weight from concept through construction. Products undergo rigorous testing against extreme conditions. This ensures their toughness and reliability in demanding environments.

Efficient Space Utilization for All Gear

Efficient space utilization is crucial for maximizing payload capacity. Designers create interiors that accommodate various gear types without wasted space. Modular compartments and adjustable dividers allow users to customize the layout. This ensures every piece of equipment fits snugly. Smart internal configurations prevent items from shifting during transport. This design approach means professionals can carry more essential tools in a compact footprint. It optimizes the case’s internal volume, making every inch count.

Stackable Designs for Storage and Transport

Stackable designs offer significant advantages for storage and transport. These cases increase warehouse capacity by utilizing vertical space. They allow products to be stored several units high, reducing the need for multiple aisles. Stackable cases also improve order fulfillment. They serve as pallets for easy inventory movement. Organized, accessible storage leads to quicker item location and retrieval. This results in faster order processing. Furthermore, stackable designs reduce product damage. Multiple compartments prevent items from piling on top of each other. This lowers costs associated with damaged goods. They also reduce wasted motion and minimize operator time. This leads to improved production throughput and faster delivery times.

7. Ventilation and Environmental Control for Your Studio Equipment Trolley Case

Preventing Overheating in Rack Cases

Studio equipment generates heat, especially when operating in enclosed spaces. Effective ventilation prevents overheating in rack cases. Professionals use active airflow solutions for small to medium racks. These solutions involve fan trays or panels installed directly into the rack. Rooftop fan units leverage convection, pulling hot air upwards and out. Horizontal fan trays target hot spots or create front-to-back airflow. These solutions effectively manage heat loads up to 3 kW per rack. For higher heat loads, direct cooling with rack-mounting air conditioners actively cools air within the rack.

Strategic airflow management is crucial.

- Extract hot air and replace it with cool, ambient air. This maintains equipment performance.

- Most modern equipment pulls cool air from the front and pushes hot air out the rear.

- Create designated cold aisles for cool air and hot aisles for exhaust air.

- Separate hot and cold air. This prevents hot exhaust air from re-entering the equipment.

Install one intake fan unit at the bottom front of the rack. This draws in cool air. Install one exhaust fan unit at the top rear. This expels hot air. Use blanking panels to fill all empty U-spaces. This prevents air recirculation. Ensure a minimum of a few inches of space around the front and back of the rack. This allows unrestricted airflow. Filter intake fans in dusty environments. Clean them regularly.

Maintaining Optimal Conditions for Electronics

Maintaining optimal temperature and humidity protects sensitive electronic studio equipment. Experts recommend specific ranges.

- Temperature: 70-77°F (21-25°C)

- Relative Humidity: 35-65%

These ranges prevent defects in wave soldering and SMT applications. Dr. Craig D. Hillman suggests maintaining humidity around 60% RH. This prevents ESD issues and problems with solder paste. He suggests a temperature range of 74-78°F. Electronic devices are susceptible to internal damage from moisture. This includes ‘popcorn cracking‘ due to moisture-induced internal stress. Interfacial delamination can also occur.

High-end equipment cases offer advanced environmental control features. These include broad to precise temperature control and humidity control solutions. They also provide protection from extreme ambient conditions. Customized environmental control units (ECUs) are available. These features protect priceless military payloads during transport. They deliver precision climate control for shipping containers. They also maintain stringent temperature, humidity, and cleanliness tolerances for microchip manufacturing equipment.

Prioritizing superior protection, robust maneuverability, intelligent organization, durable construction, and future-proof adaptability ensures a Studio Equipment Trolley Case meets the demands of 2025 and beyond. Investing in these features safeguards valuable gear and streamlines professional workflows. A well-chosen trolley case is a critical asset for any professional in the studio or on location.

Post time: Nov-14-2025